Strict QC, In Five-Star,

you can rest assured.

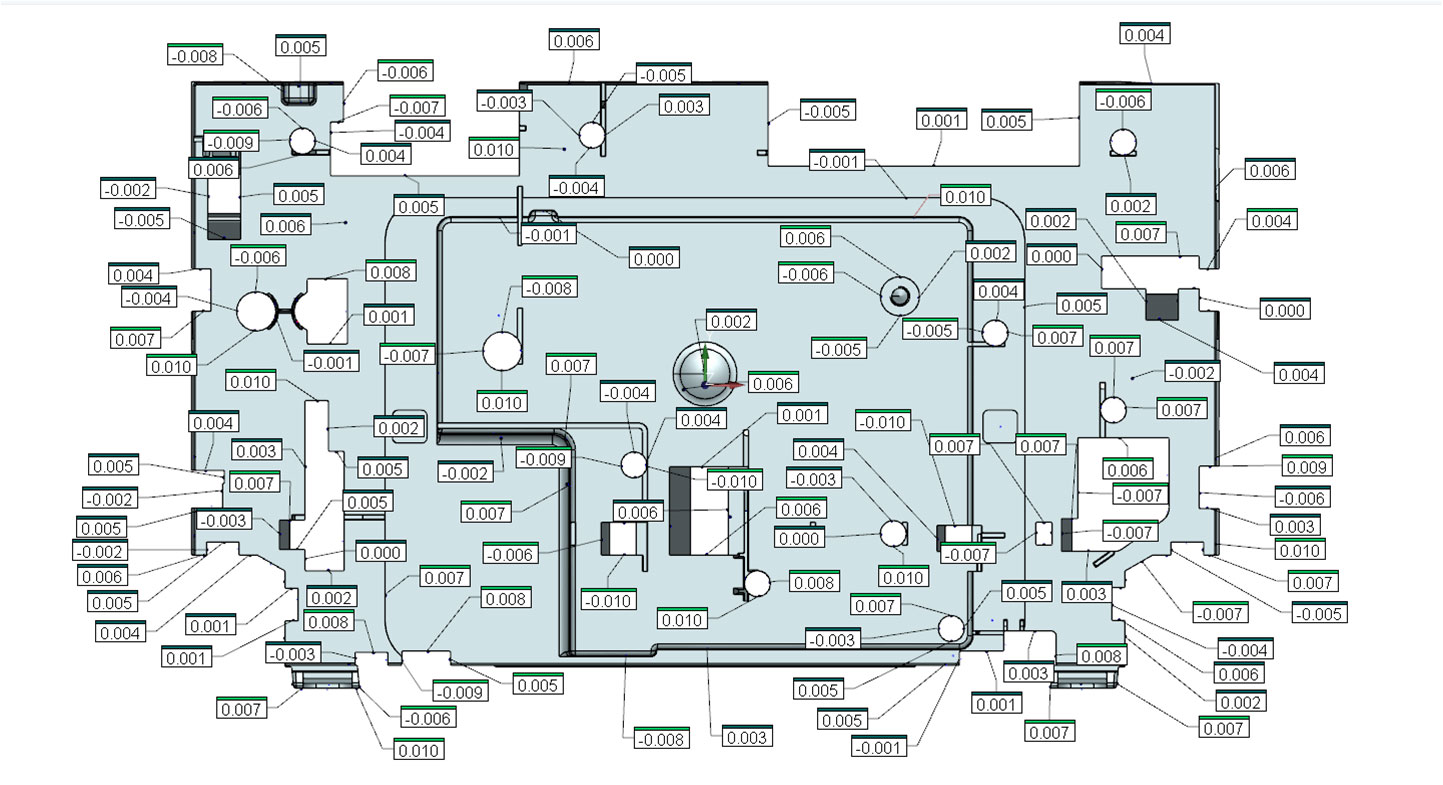

QC operation is divided into three parts: incoming inspection, process inspection, part inspection and part test.

All links are strictly implemented, and the abnormality will be recorded in the "abnormal report form" in detail and accurately.

After being confirmed by the team leader, it will be sent to the relevant departments for processing.