QUALITY CONTROL

品质控制

# 01

Quality Flow

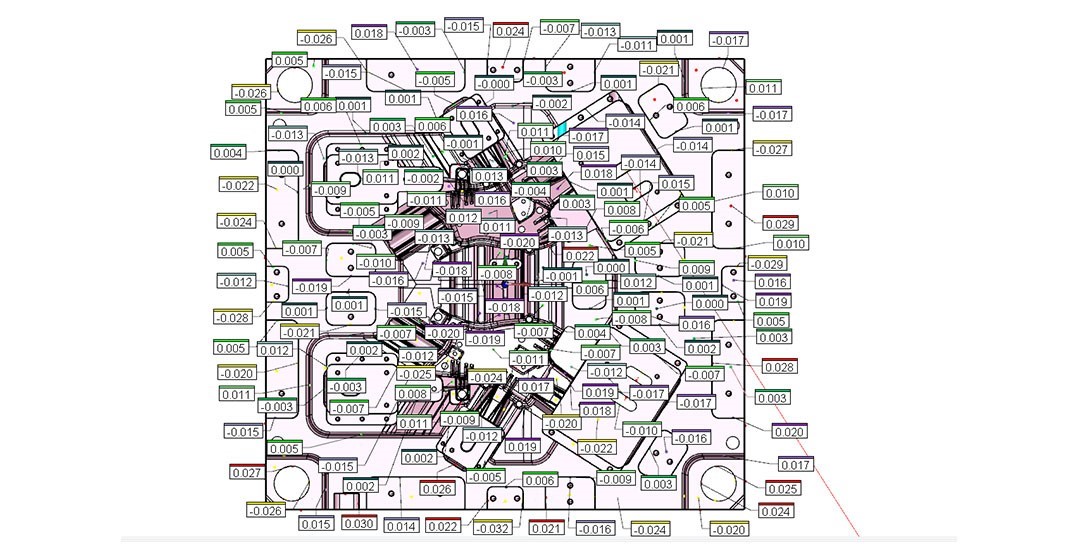

QC operation is divided into three parts: incoming inspection, process inspection, parts inspection and part testing. All links are strictly inspected. If there is any abnormality, please record it in writing in detail and accurately on the "abnormal report". After being confirmed by the QC team leader, send it to the relevant department for processing. Incoming material inspection: incoming mold base, steel material, Heat-treated parts and outgoing processed parts need to be inspected for process inspection: inspect CNC, EDM, wire-cut parts. The process inspection mainly controls the product's external dimensions, assembly dimensions, appearance parts inspection and parts testing: after the product is completed, the product's external dimensions, assembly dimensions, appearance, etc. are inspected, and the parts are tested with the help of testing instruments, and the measurement report is completed.

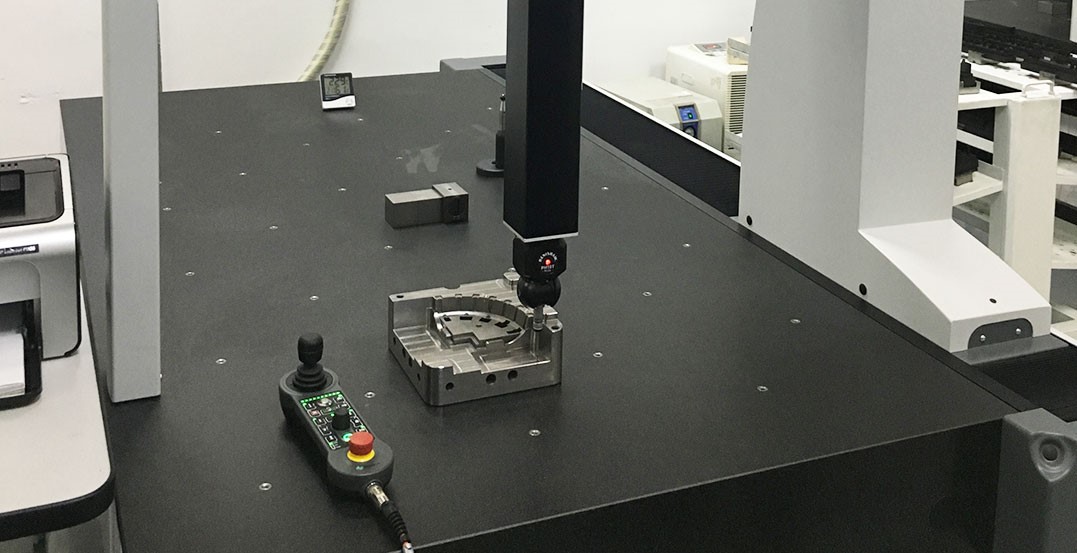

QC measurement room needs to maintain constant temperature and humidity (22 degrees plus or minus 2 degrees, 40% to 70%). The room is clean and tidy. All data are kept in a complete and orderly manner. Various measuring tools are well maintained and regularly Maintenance calibration. All items should be marked.

# 02

Testing Equipment

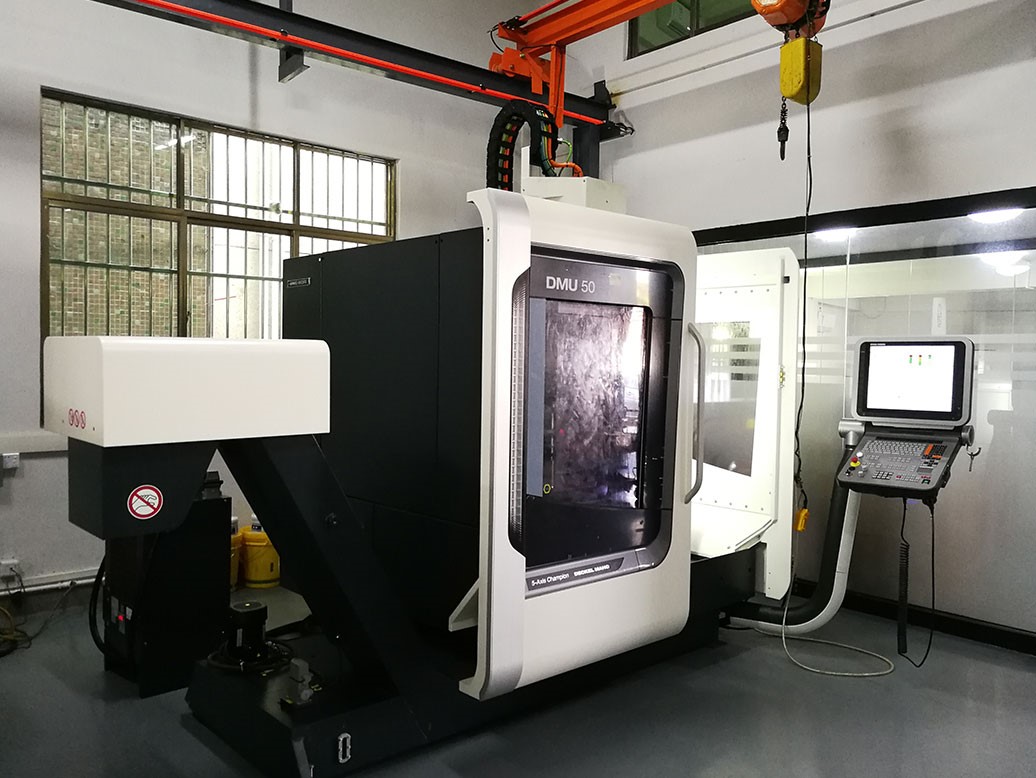

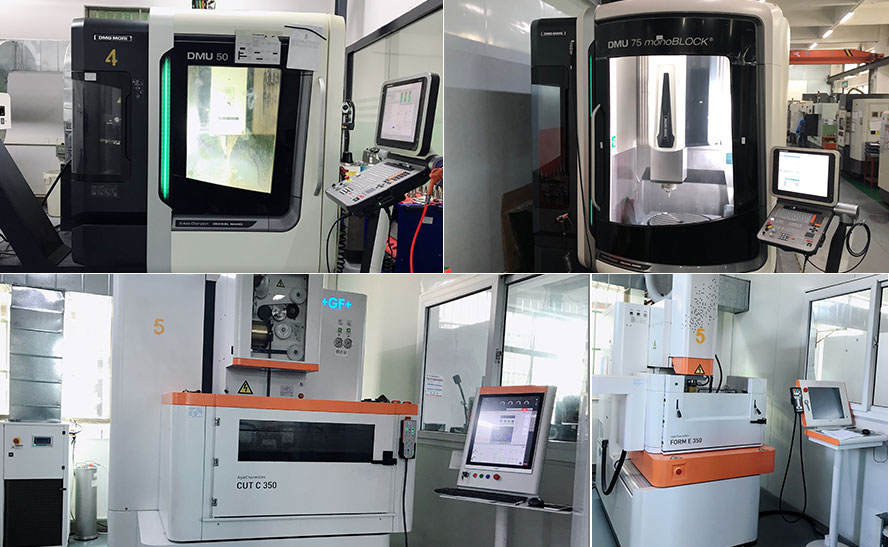

Five-Star is equipped with imported Hexagon three-dimensional, projector, hardness tester, etc. Every process from ordering to delivery of each product is tested by precision equipment, and the test report is filed according to the quality control process.

# 03

Related Reports

Every process from Five-Star to delivery has been strictly tested by the quality control department, such as hardness, precision, appearance, size, etc., and relevant reports are filed.

PROCESSING ABILITY

加工能力

COMPANY PROFILE

关于星凯

Founded in 2008, Five-Star Technology has advanced DMG 5-axis CNC machine tools imported from Germany, Charmilles spark machines, Charmilles slow wire walking, Hexagon's fully automatic three-dimensional and other precision machinery and equipment. Experienced five-axis machining engineer team and project management team. Specializing in five-axis machining and other high-precision parts machining, especially five-axis machining, which is widely used in various high-tech precision industries, such as robot parts, drone parts, medical equipment parts, aviation parts, automation equipment parts, aerospace , ship parts, connector parts, military parts and so on.